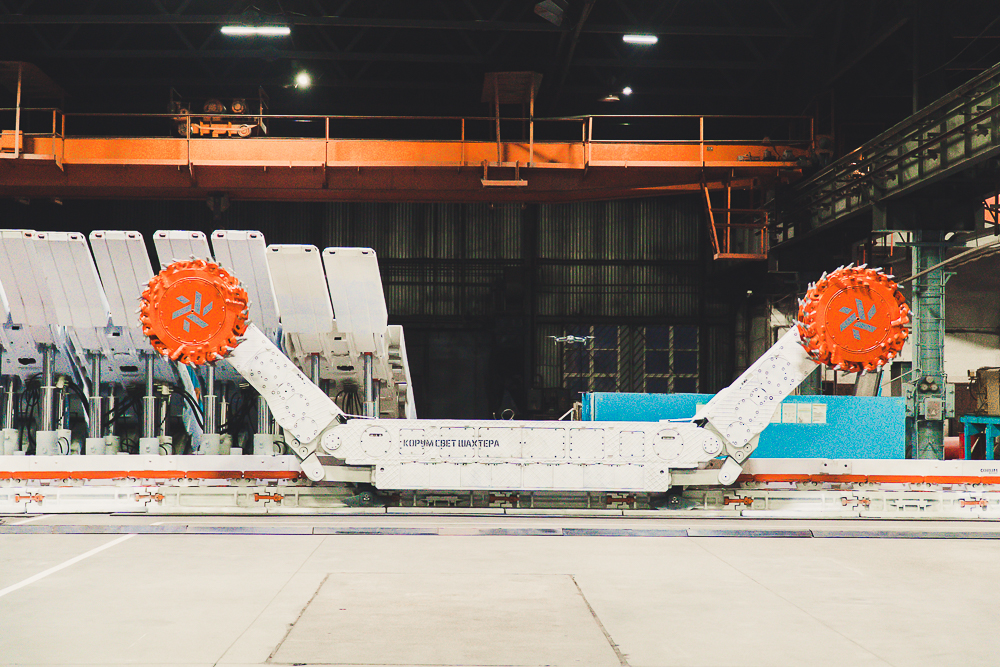

The second automated complex has been presented at Corum Svitlo Shakhtarya plant. An automated coal-face complex is a complete set of mining equipment used to mine and transport coal from a longwall face to improve the performance of equipment and achieve target performance indicators.

The coal-face complex comprises a KDK500 coal cutter, a SPC230 285-meter-long scraper conveyor, a SPC230 reclaiming scraper conveyor, and a 3KD90ТS powered support.

“It is very important for me to present our second automated complex on the quality day,” commented Mykhailo Potapov, acting general director of Corum Group. “I am confident that this complex will set new records. In the midst of a pandemic and restrictions, we mobilized our efforts and prepared the complex for delivery as scheduled. The delivery was performed online. We daily prove to ourselves and the entire world that Ukraine is capable of manufacturing high-quality modern equipment that finds a ready market. I am grateful to the Corum team for their work.”

When designing a KDK500 coal cutter, Corum engineers improved its power equipment and introduced a system of diagnostics and control of main components demonstrating the results on a display. The cutter will be capable of operating in a wide range of coal bed thickness of 1.4 to 3.2 meters. The Corum KDK500 is one of the coal cutters that are the most popular among miners.

A 3KD90ТS powered support included in the face complex has improved support capacity capable of supporting an unstable and heavy upper formation top with a distorted structure.

“The 3KD90ТS powered support is designed for operating in 1.4- to 2.4-meter-thick coal beds,” says Tetiana Kaluhina, director of Druzhkovsky Machine-Building Plant. “High-strength steel is used to manufacture the support. A choice and application of a steel grade is determined based on the structure strength and the client’s requirements in accordance with GOST 31561-2012 and the EN1804 standard. The quality management system of Druzhkovsky Machine-Building Plant is compliant with the requirements of the international standard which is confirmed by the ISO 9001:2015 compliance certificate. I am proud of our company and our plant: we fulfill extremely complex orders, build up trust among our clients, and develop our production facilities. Such large orders as powered supports mean stable operations for Corum Druzhkovsky Machine-Building Plant. It means stability for employees, their families, the city, and community.

The first automated complex helped our client improve its production performance and reduce the fault rate by extracting up to 10 thousand tons of coal per day and set a record in 2019: miners produced 2.5 million tons of coal and achieved their target indicators two months ahead of a schedule. The second coal-face complex presented by Corum will provide an opportunity for producing even more coal to attain Ukraine’s energy independence.”

“Special wear-resistant steel grades are used to manufacture the equipment that makes part of the complex and fitted with the most modern parts supplied by European manufacturers. By using innovative technologies, design solutions, and engaging the professional team of Corum Group, we have an opportunity to design and manufacture state-of-art complexes that are popular with our clients and are well-represented on the market. Today, Corum Svitlo Shakhtarya is successfully working and continues its development. We introduce innovations and receive new orders that ensures our personnel’s complete engagement which means jobs, the region’s stability, and confidence in the future for all employees and their families,” says Oleksandr Kovalchuk, director of Corum Svitlo Shakhtarya Plant.

Corum Group sustainably develops, masters new product manufacturing, and aims at receiving large orders. Miners receive high-performing equipment, and the company employees receive salaries and social benefits and have opportunities for professional growth.

The popularity of mining equipment produced by Corum Group on external markets has been growing, and the share of export supplies has been raising from year to year. Corum equipment operates in 15 countries around the world.